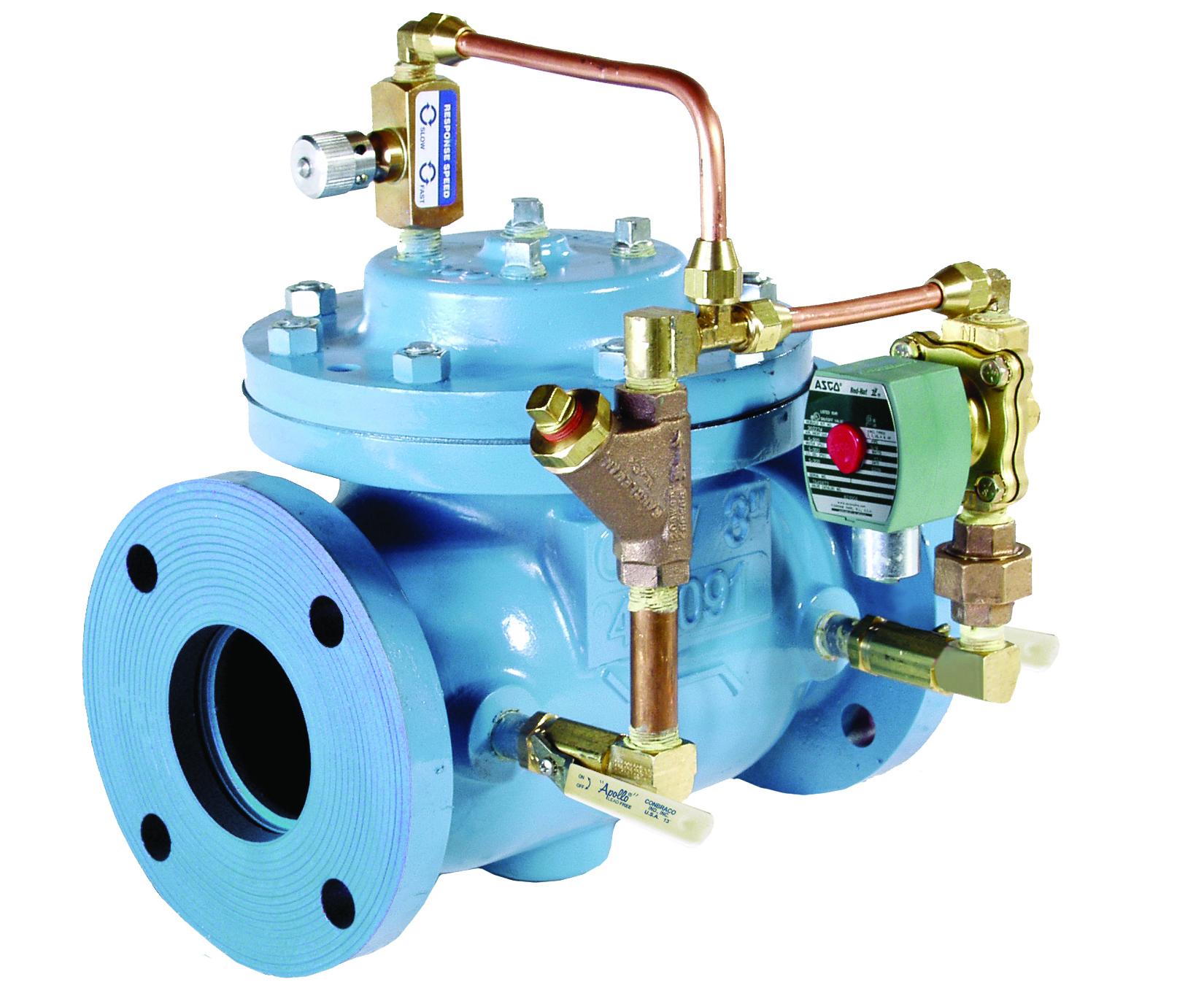

Simply put, control valves control what’s in the pipe. The most common control conditions are flow, pressure, temperature and level. Control valves can be anything from a simple kitchen faucet to multi-port, multi controlled precision instrument.

The globe valve design utilizes a sliding stem with a plug and seat on one end. The stem moves the plug toward or away from the seat allowing the gap to get bigger or smaller, which controls the amount of media allowed to pass through the valve. A hose bibb or lawn faucet is the most basic example of this design, however, some of the most high tech valves work on this same basic principal.

Quarter turn valves, including ball valves, butterfly valves and plug valves, are another common method of control. Again, the method of control is by restricting (or expanding) the opening through the valve.

Control valves can be manually operated, set to the desired position and then left alone. Or they can be controlled by upstream and downstream sensors which allow the valve to open and close as conditions in the system fluctuate. An example of this would be a process steam control valve in a heating application. The system requires a constant temperature, but is influenced by the atmosphere like winter or summer. A temperature sensor is placed downstream of the valve. This sensor controls a spring devise that in turn opens and closes the valve as required.