Step 3 – Define the Flange Facing

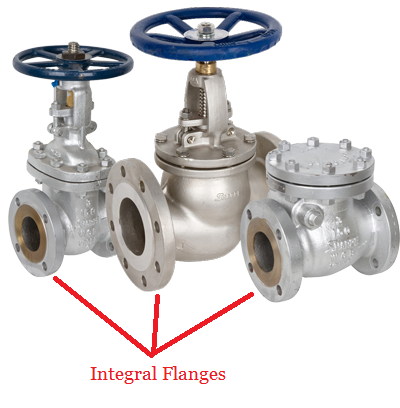

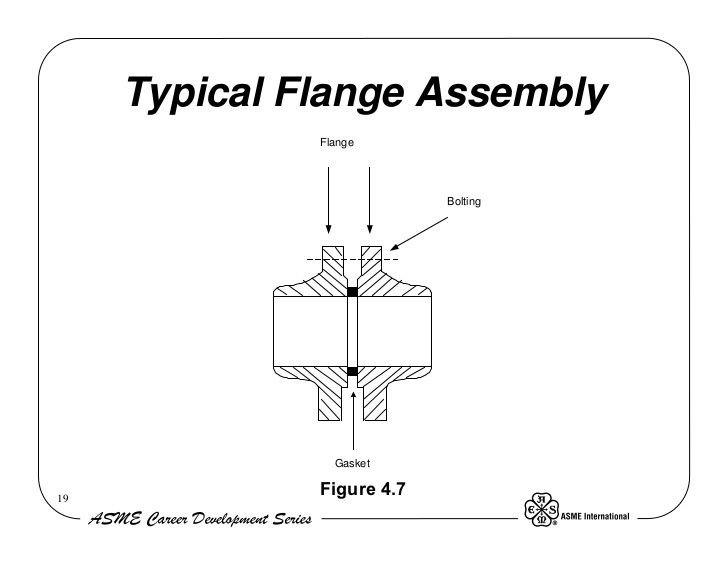

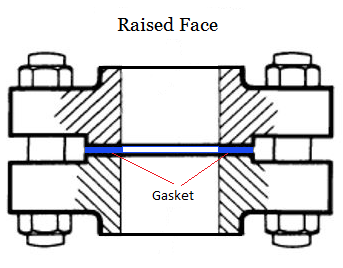

The face of the flange is the sealing surface. In nearly all cases a gasket is used between flange facings (the most notable exception is resilient seated lug and wafer butterfly valves.) Any type of pipe flange can be ordered with any of the facings mentioned here.

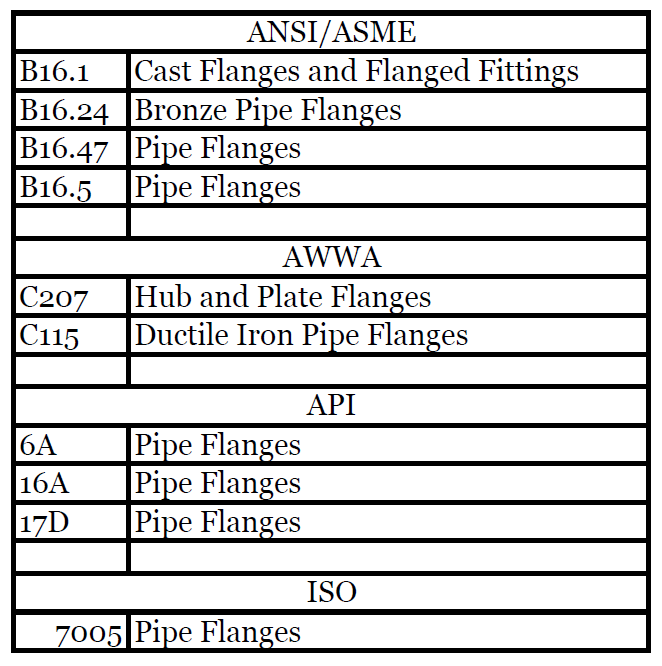

This chart shows the most common flange faces.

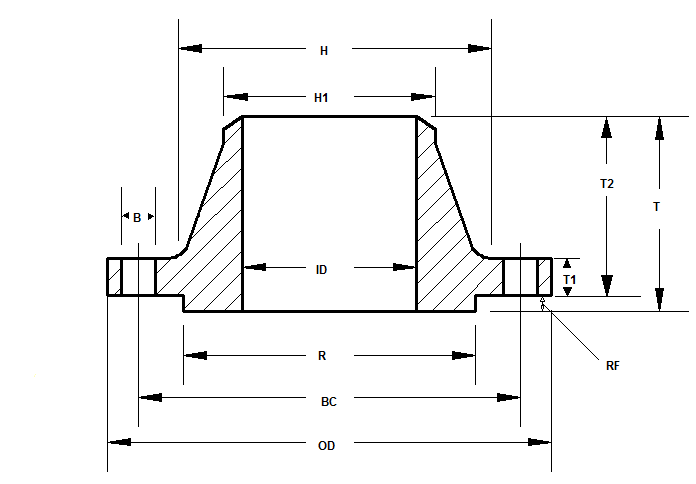

Raised Face (RF) is the most common industrial flange facing. Class 150 and 300 have a 1/16” raised face and class 400 thru 2500 have a ¼” raised face. This raised section is the sealing surface of the flange. RF flanges are designed to use a Ring gasket; however a Full Face gasket will also work. By creating a gap at the bolt circle, the RF flange exerts more pressure on the sealing surface than a flat face flange.

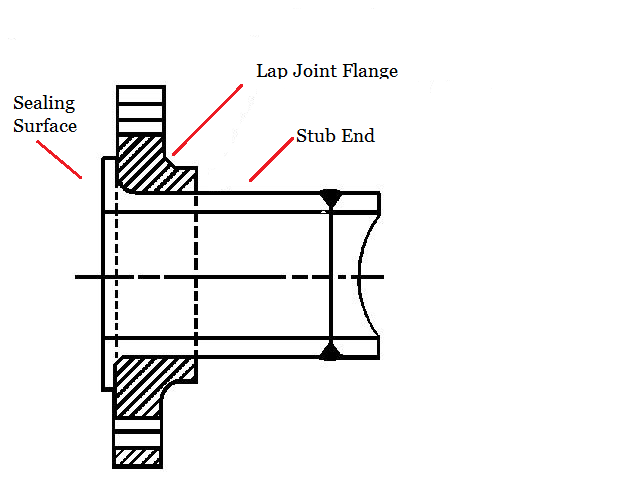

Lap joint flanges have flat faces. The face of a lap joint is not used for sealing. The lap joint is used in conjunction with a stub end and the sealing surface is on the stub end. The sealing surface on the stub end is similar to a RF flange.

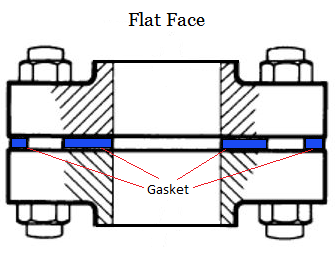

Flat Face (FF) flanges utilize the entire face for sealing. They are used for lower pressure (up to 250 psi) applications. FF flanges are designed to use a Full Face gasket; however a Ring gasket will also work. It is possible to mount a FF to a RF flange and have them seal, however it is not advisable.

Flange facings can be modified from their original manufacture as long as the standard's minimum dimensions are maintained. For example a RF flange can be machined to a FF or RTJ flange.

Standard facings can have a serrated concentric or serrated spiral finish.

Part 4 coming soon...

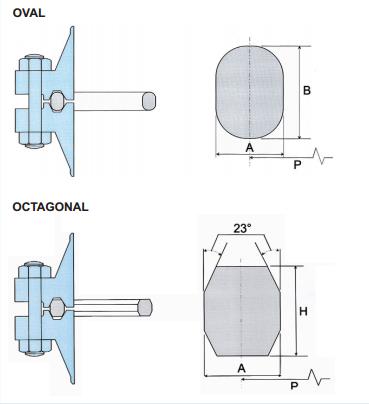

Ring Joint or Ring Type Joint (RTJ) facings use a metal ring gasket. The gasket is usually oval or octagonal in shape and it fits into a groove on the flange. RTJ flanges have a raised race and are used for high pressure and high temperature applications.

Male & Female and Tongue & Groove facings are not very common and are used in only a few niche applications. These flanges use a Ring gasket that fits into the female or groove face.