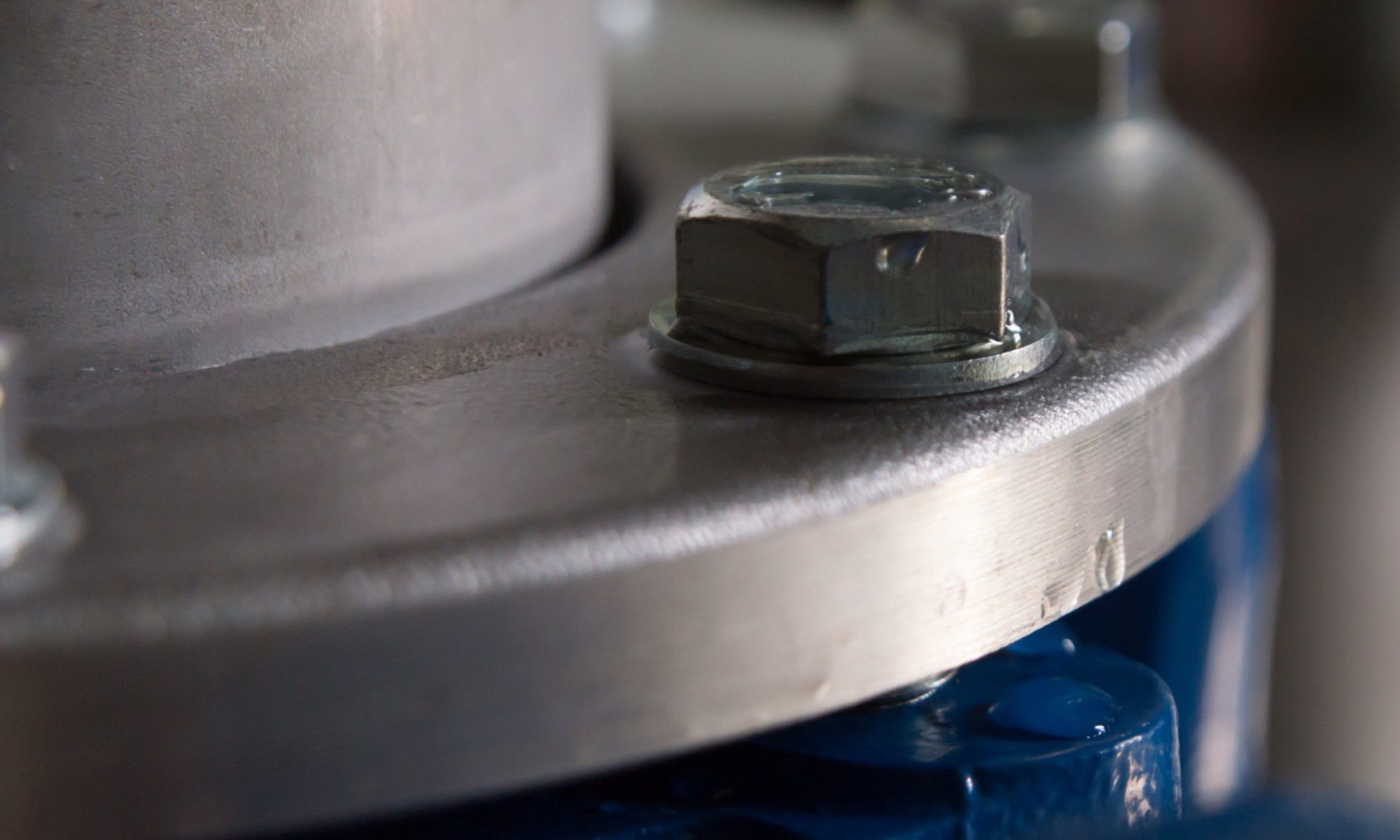

Pipe flanges are used for connecting pipe, valves, fittings, strainers, pumps and equipment. Nearly all pipe flanges are round discs; however they can also be square, rectangular or oval. Flanges that are not round are designed for very specific applications such as hydraulics, ammonia service, hand rails and meters. In this tutorial we will examine only pressure rated round flanges that connect to pipe.

Step 1 - Define the Standard or Specification.

Over 100 years ago some very smart engineers figured out that different manufacturers build different components of a piping system. And in order for these components to easily bolt together, standard dimensions would be required. So they made a lot of calculations factoring in flow characteristics and pressure ratings and then designed a few flanges. They sent these dimensions and calculations to their peers, the piping component manufacturers and probably a few insurance companies. Eventually they all nodded yes and a standard was born.

Over the years more standards were added, more sizes and pressure classes were added and more definitions were added. Mostly the standards detail the flange dimensions and tolerances, but there are also standards that detail the chemistry of the materials.

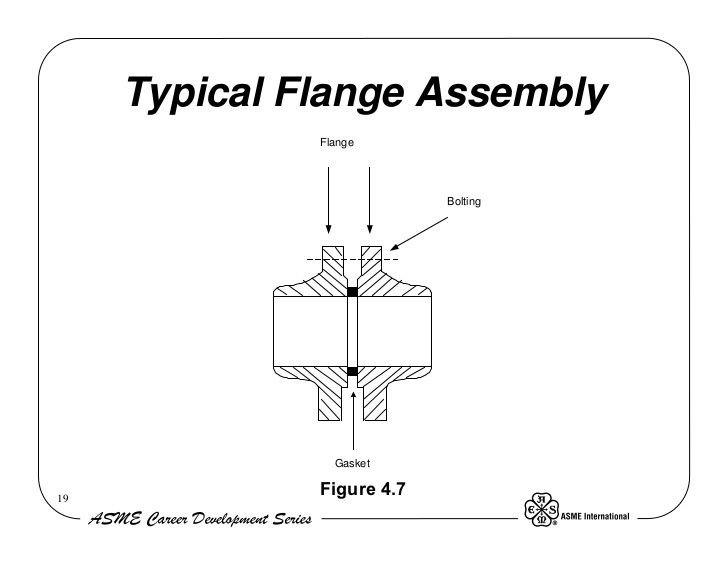

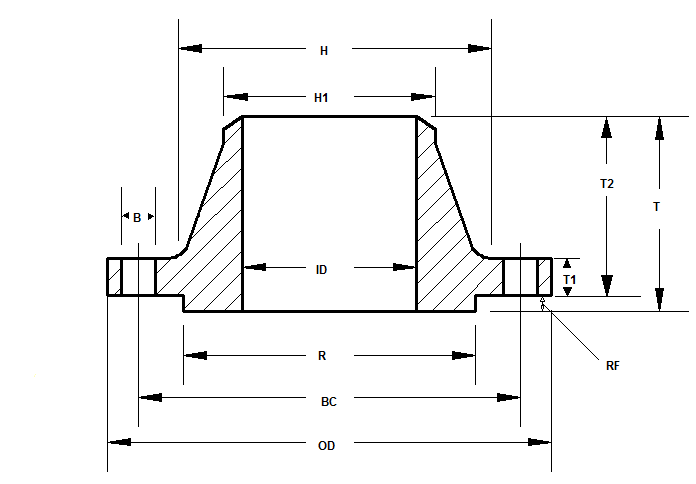

Details of the flange dimensions include the number of bolt holes, the size of the bolt holes, the diameter of the bolt circle and the shape of the flange face (the sealing surface.)

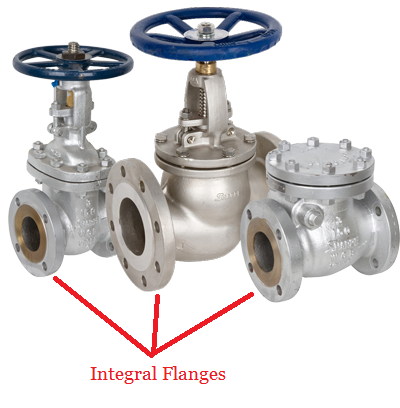

Pumps, valves, strainers, pipe fittings and piping equipment are often produced and sold with integral flanges. In order to connect these to a piping system, a mating flange is required. This mating flange must have the same bolting dimensions and matching facing for the flange to connect and seal.

The following criterion is required when ordering flanges, but only if you want them to connect and seal, which we assume you do.

- Standard or Specification

- Pressure Class

- Facing

- Material

- Pipe Size

- Connection Type

- Description

This list may look difficult at first, but we’ll walk you through it so it’s a little easier.

All of these dimensions are critical for bolting and sealing.

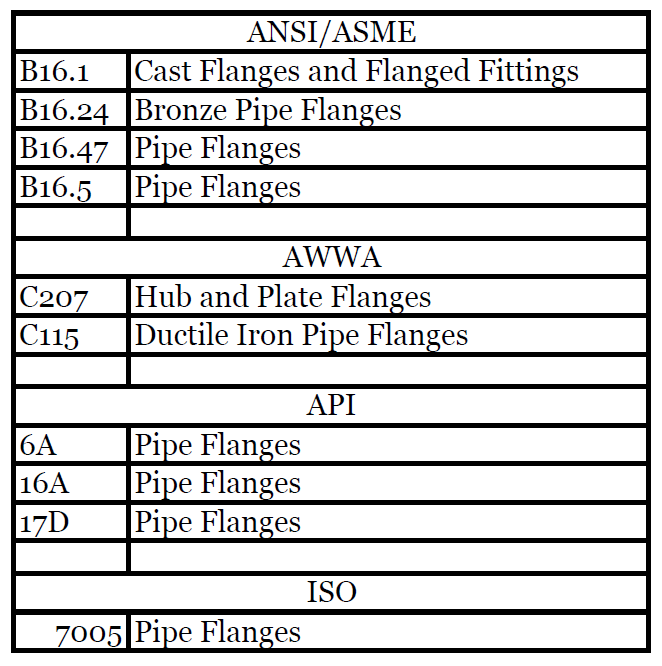

Each of these standards list flanges by pipe size, pressure class, facing and pipe connection. Pipe size and pressure class determine the bolting pattern. Facing determines the sealing surface. Some bolt patterns and facing are shared across these standards and are primarily based on the ANSI/ASME B16.5 standard. Because not all the dimensions are shared, we recommend you start by defining the applicable standard.

If you are mixing standards or adapting, we suggest you consult a professional, like one of our friendly sales people. If you are unsure which standard to adopt, we again suggest you consult a professional… like one of our friendly sales people.

This chart shows the most common dimensional standards used for industrial and commercial metal flanges.

Your post is valuable , thanks for the info